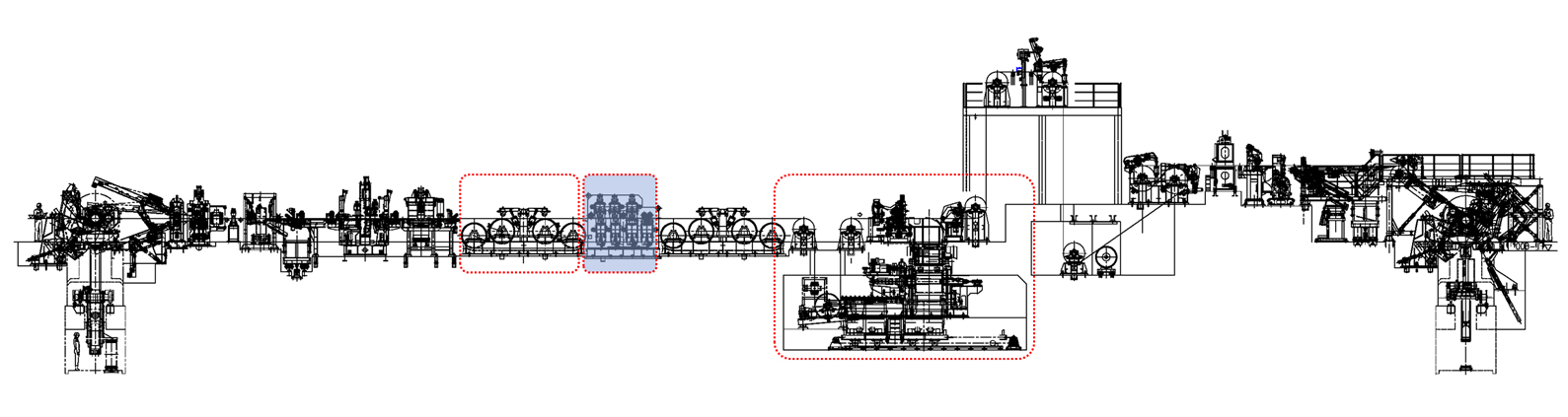

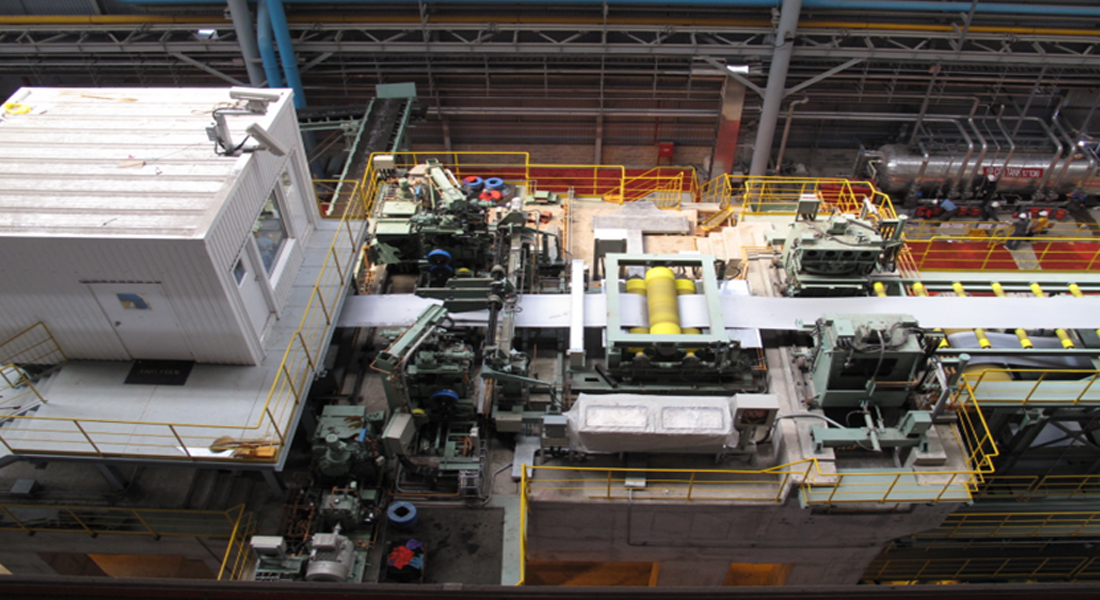

Main Equipment

■ Product Description

Recoiling and Trimming are important operations to be carried out after the Cold Rolling of coils. A number of steel coil customers demand exact trimmed CR / Galvanised Coils. To this demand, it is essential to trim the edges of the coil before dispatching to such customers.

The coil surface is inspected carefully. Stroboscopic light ensures visibility of defects if any without stopping the process. An Electrostatic Oilers is provided to apply all types of RP and DOS oils uniformly on both surfaces.

Technologies :

- Coil auto loading / unloading

- Final width adjustment by side trimmer

- In-line tension leveling

■ Main Parts Details

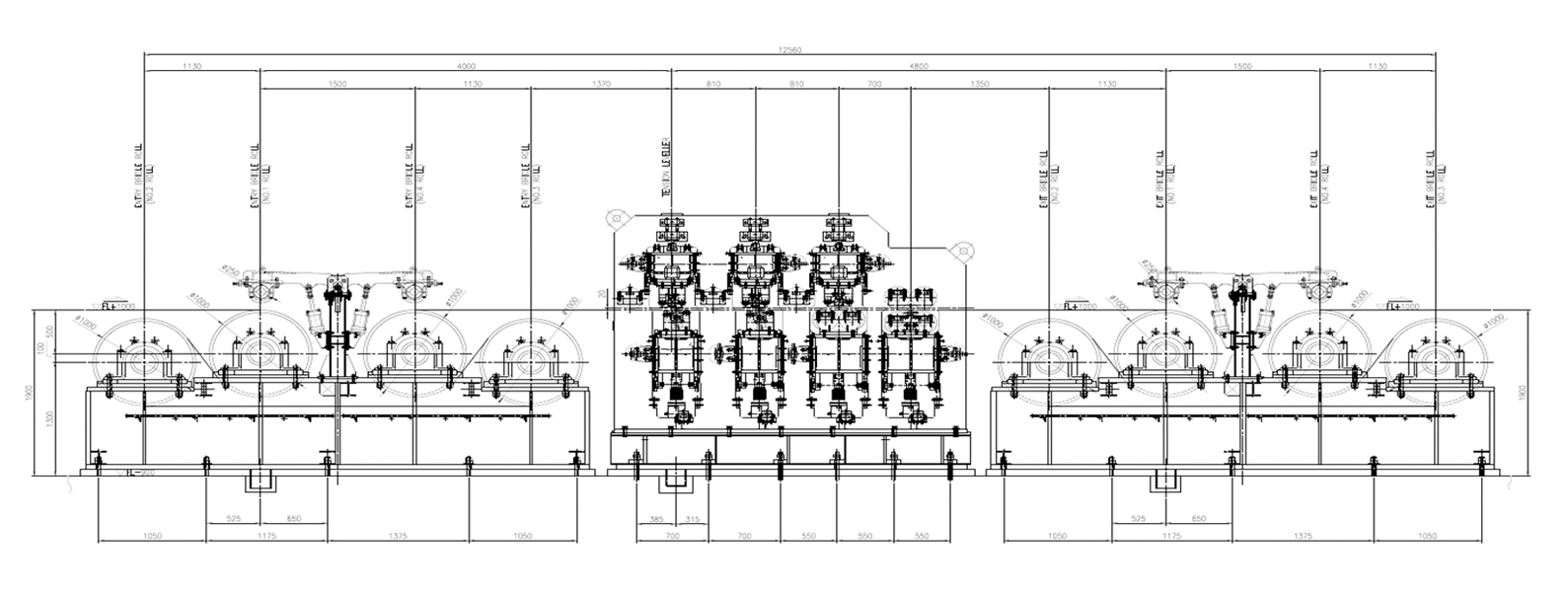

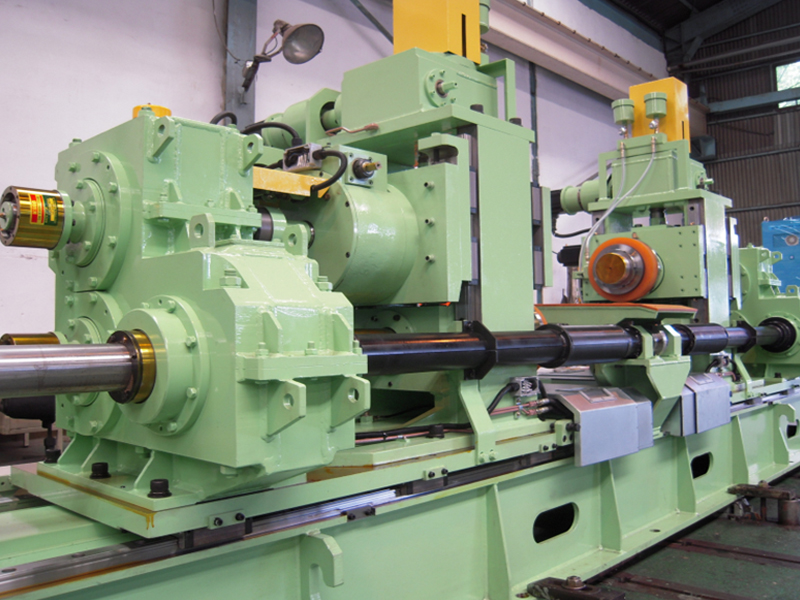

Tension Bridle

■ Product Description

Bridle roll is the important equipment in the Recoiling line, whose main function is to divide the line into several sections according to the difference of the strip tension, and control the strip tension.

■ Main Parts Details

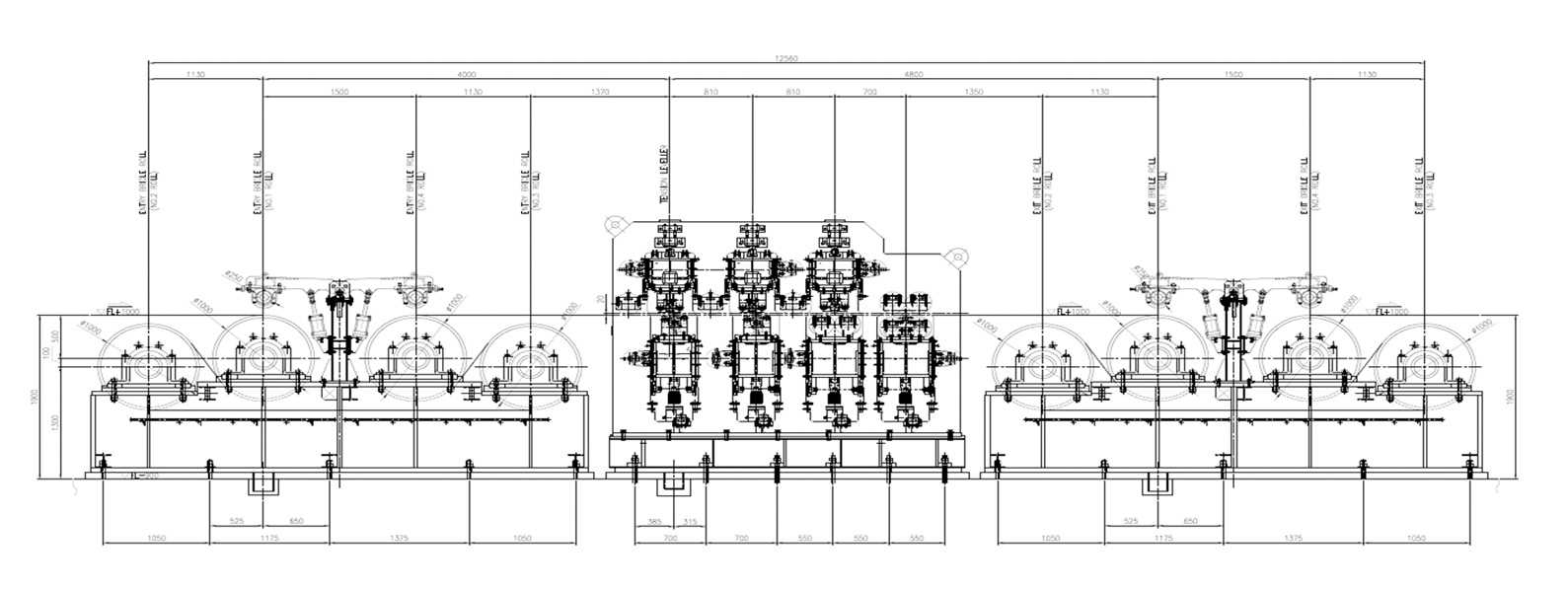

Tension Leveler

■ Product Description

The value addition of this line is to further improve the strip flatness with the help of a tension leveler unit.

Technologies :

- No-chartering Tension Leveler Implementation

- Easy and safety at roll changing and maintenance work

- Individual roll cassette changing mechanism during the line running

■ Main Parts Details

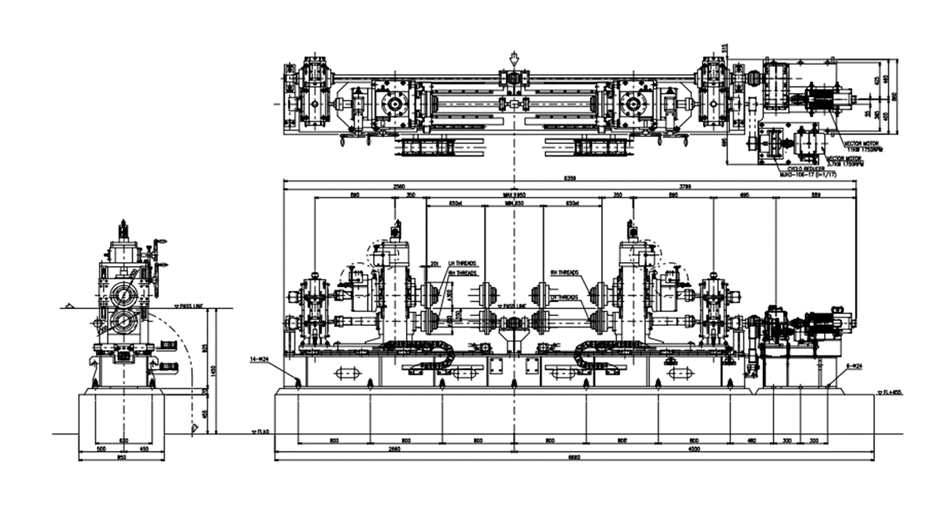

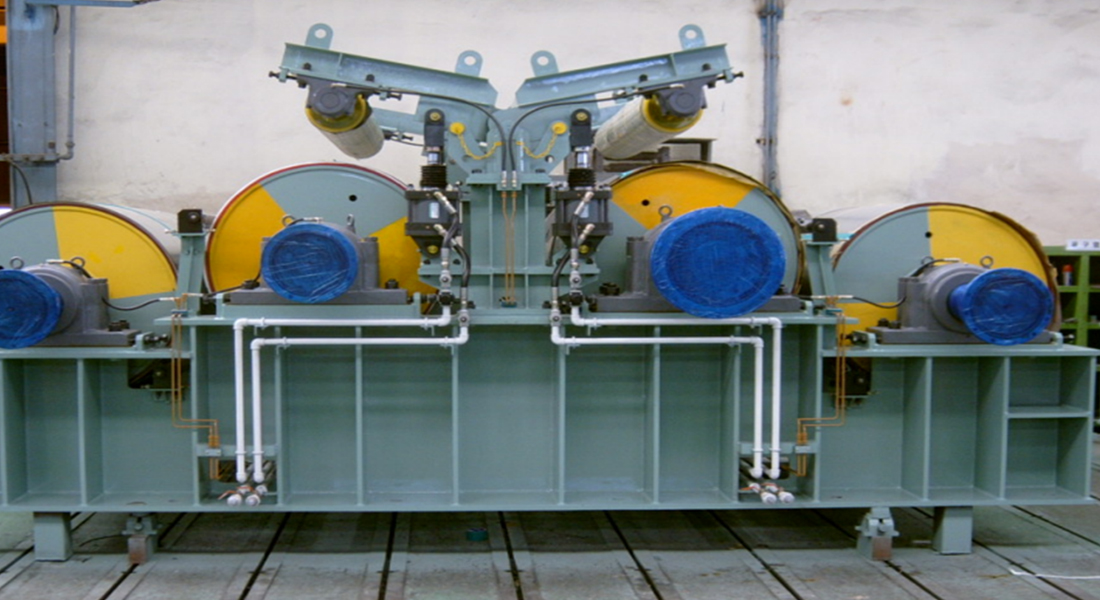

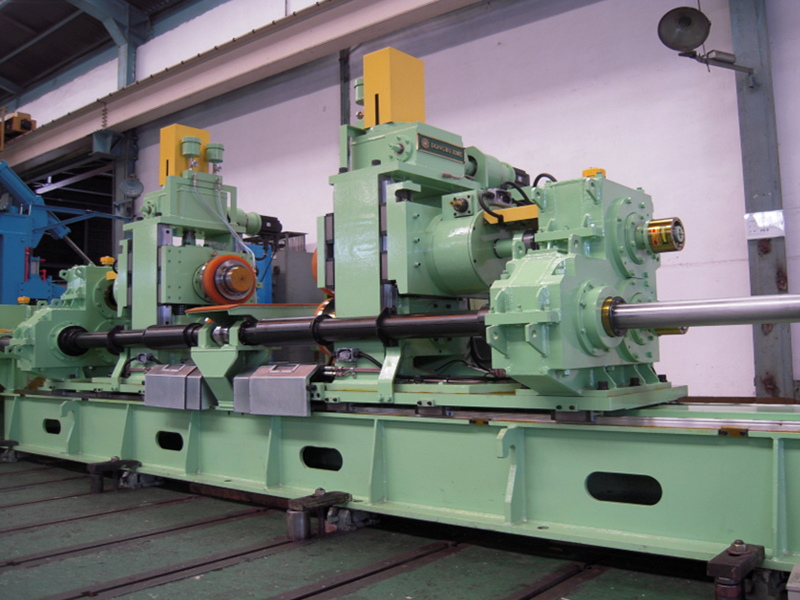

Side Trimmer

■ Product Description

Side trimmer cutting the strip edge according to required width. Precision width adjustment shall be done within a very tight allowance and maximum trimmer chip shall be 3 ~ 40 mm for each side.

High precision degree between knife gap and lap position is composed of screw jacks on the sliding, roller bearing, and moving parts, and is driven by servomotor.

■ Main Parts Details

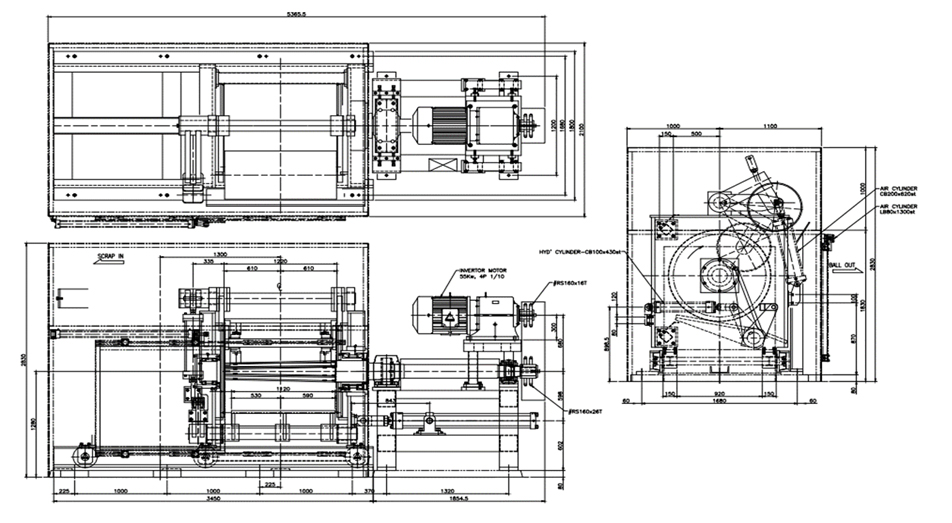

Scrap Baller

■ Product Description

This equipment will be installed behind of side trimmer on operation side, and the scrap chute and scrap baller will be arranged.

The scraps are sent to the fronts of scrap baller through scrap chute. The scrap baller winds up scraps and the ball, on which the scraps are wound up, is kicked out unto the scrap receiving place.

■ Main Parts Details